专 访

张之涵

Frank Zhang

科思创涂料与胶粘剂事业部亚太区

应用与市场开发 副总裁

Head of Application and Market Development APAC

Business Unit Coatings and Adhesives

《中国涂料》China Coatings

在当下复杂且多变的市场大环境中,科思创作为全球领先的高品质聚合物的生产商之一,请问企业究竟该采取何种策略来实现跨周期增长?又该如何精准挑选市场、深度耕耘市场,进而开发出更具市场竞争力的产品?

In today's complex and changing market environment, as one of the world's leading manufacturers of high-quality polymers, what strategies will Covestro adopt to achieve its growth across cycles? How to target the right market and develop more competitive products for the market?

科思创 Covestro

作为一家有着80多年创新历史、全球领先的聚合物制造企业,科思创正积极推进“可持续未来”的战略,以积极应对当下复杂且变化快速的市场挑战,并推进转型。我们的战略核心包含了:

以客户为中心,通过持续投资构建起高品质、更稳定的区域供应能力,并采取一系列举措来提升我们的运营效率和市场竞争力,从而成为客户可靠的合作伙伴。

以可持续的方式驱动增长。我们将通过有机增长、非有机增长和创新来扩展我们具有吸引力的可持续产品组合,以满足市场对于环保型、高性能产品日益增长的需求。到2025年,我们80%的研发项目支出将有助于实现联合国可持续发展目标(SDG)。

实现气候中性和全面循环。科思创提出了实现“全面循环”的企业愿景,走在低碳循环经济发展的前沿。我们的目标是到2050年实现供应链上下游全流程的净零排放,重点举措包括采用替代性原材料和可再生能源,以及促进创新的回收技术。从长远来看,我们的目标是100%使用替代原材料生产我们的产品,并在全球所有生产基地采用100%可再生能源。

As a company with over 80 years of innovation history, Covestro is implementing its "Sustainable Future" strategy to respond to today's complex and rapidly changing market challenges and drive transformation. Our strategic core includes:

Customer-centricity: Building high-quality, more resilient regional supply capabilities through continuous investment, and taking a series of measures to improve our operational efficiency and market competitiveness, thereby becoming a reliable partner for customers.

Driving growth sustainably: We will expand our attractive sustainable product portfolio through organic growth, non-organic growth, and innovation to meet the growing market demand for environmentally friendly, high-performance products. By 2025, 80% of our R&D project expenditure will contribute to the United Nations Sustainable Development Goals (SDGs).

Achieving climate neutrality and fully circular: Covestro announced its vision of being "Fully Circular," and aims to lead the development of a low-carbon circular economy. Our goal is to achieve net-zero emissions throughout the supply chain by 2050, with key initiatives including the adoption of alternative raw materials and renewable energy, as well as promoting innovative recycling technologies. In the long term, our goal is to produce our products using 100% alternative raw materials and adopt 100% renewable energy at all our global production sites.

值得一提的是创新力是科思创在新周期中实现增长的动力。我们关注创新的深度。即通过解决技术挑战,无论是性能、效率,还是市场的法规合规方面的,为客户提供全方位的综合解决方案。同时,我们也关注创新的广度。我们本土的研发团队与产业链的合作方一同开发前瞻性的产品和解决方案,以拓展更具增长潜力的涂料、胶粘剂新应用场景。

It's worth mentioning that innovation is the driving force for Covestro's growth in the new cycle. We focus on the depth of innovation - providing comprehensive solutions for customers by addressing technical challenges in performance, efficiency, and regulatory compliance. At the same time, we also focus on the breadth of innovation. Our local R&D team works with partners along the value chain to develop forward-looking products and solutions to expand new applications for coatings and adhesives in those niche markets with greater growth potential.

《中国涂料》China Coatings

自2025年起,科思创提出了“综合解决方案,成就您的无限可能”的宣传口号。在此,诚邀张总分享一下科思创在创新方面有哪些具体举措,又如何助力客户应对各类挑战,并成功开拓业务新边界?

Since 2025, Covestro has launched the campaign "Total Solutions Unlock Your Possibilities." Could you share what specific innovation initiatives Covestro has undertaken, and how it helps customers address various challenges and successfully expand new business boundaries?

科思创 Covestro

在当今充满挑战与不确定性的市场环境中,客户需求已从产品转向定制化的解决方案。“科思创综合解决方案”理念体现在我们为客户提供的不仅是高品质产品,更是从产品开发、配方优化到应用施工的技术服务。我们旨在为客户提供一站式的服务,以满足多样化的需求。

通过本土化战略的实施,我们在以下几方面显著增强了实力:

高效研发流程。我们构建了从实验室产品研发到规模化生产的完整本土创新链,帮助客户大幅缩短新品上市时间。

深度市场融合。我们的创新原则"贴近区域市场"。我们在传统优势的高端应用市场外,更多推出了贴近市场的高性价比的新型涂料和胶粘剂解决方案,来帮助客户扩大市场份额。

一站式采购体系。我们为客户提供专业的通用配方建议,并且越来越多地在配方中融入科思创的高品质固化剂和树脂产品。这不仅确保了更优的产品兼容性和可靠性,同时也简化了客户的供应链管理流程。

In today's challenging and uncertain market environment, customer needs have shifted from single products to solutions. The "Covestro Total Solutions" concept is reflected in our provision of not only high-quality products but also technical services from product development and formulation optimization to application suggestions. We aim to bring one-stop service to our customers to meet their diversified needs.

Through implementation of localization strategy, we have significantly enhanced our capabilities in the following areas:

Efficient R&D process: We have built a complete local innovation chain from laboratory product development to scale up production, helping customers significantly shorten time-to-market for new products.

Closeness to market: Our innovation principle is "close to regional markets." Beyond our traditional high-end markets, we have launched more cost-competitive coating and adhesive solutions that help can customers expand market share in other market segments.

One-stop shop: We provide customers with ready-to-use formulation guidance and also increasingly include both crosslinker and resin products by Covestro into formulations. This not only ensures better product compatibility and reliability but also simplifies customers' supply chain management processes.

科思创近年来还加大了树脂产品的创新投入,并搭建起一个覆盖多应用行业、包含不同技术体系和产品组合的“树脂之家”。树脂作为涂料的核心原材料,在涂料创新中起着重要的作用。我们的高性能树脂不仅提升了涂料的环保性、耐久性和美观度,更为客户带来了差异化竞争优势。特别是在水性涂料和低VOC高固体分涂料领域,我们的创新树脂帮助客户满足日益严格的环保法规要求,并进一步提升施工效率,实现节能减排。

今年,我们也陆续推出了一系列针对汽车和轨道交通行业以及家具行业的综合解决方案,涵盖了聚氨酯、丙烯酸和聚酯等系列产品,水性、高固体分和潮气固化等技术平台,给到客户更多“物有所值”的具有竞争力的综合解决方案的选择。

Covestro has also increased innovation investment in resin products in recent years and built a "House of Resins" covering multiple application industries, including different technology systems and product portfolios. As a core component of coatings, resins play an important role in coating innovation. Our high-performance resins not only enhance the environmental friendliness, durability, and aesthetics of coatings but also bring differentiated competitive advantages to customers. Especially in the fields of waterborne coatings and low VOC high-solid coatings, our innovative resins help customers meet increasingly stringent environmental regulatory requirements while further improving application efficiency and achieving energy conservation and emission reduction.

This year, we have also launched a series of total solutions for the automotive and rail transportation industries as well as the furniture industry, covering polyurethane, acrylic, and polyester series products, waterborne, high-solid, and moisture-curing technology platforms, giving customers more "value for money" competitive comprehensive solution choices.

《中国涂料》China Coatings

科思创一直以来为行业提供创新解决方案为己任,开发出诸多行业标杆型产品,请介绍一下迄今为止取得了哪些显著成就和具备哪些独特优势?

Covestro has always been committed to providing innovative solutions for the industry and has developed many industry benchmark products. Could you introduce what significant achievements have been made so far and what unique advantages do you have?

科思创 Covestro

科思创作为聚氨酯技术的发明企业,有着很多耳熟能详的明星产品,例如Desmodur®ultra N固化剂、Dispercoll® U水性聚氨酯分散体。当涂料和胶粘剂行业不断发展时,科思创致力于引领行业创新,助力行业标准。

As the inventor of polyurethane technology, Covestro has many well-known products, such as Desmodur® ultra N crosslinkers and Dispercoll® U waterborne polyurethane dispersions. As the coating and adhesive industry continues to develop, Covestro is committed to leading industry innovation and helping set industry standards.

我们的产品服务于很多的下游应用行业。以汽车行业为例,Desmodur® ultra N系列固化剂产品已广泛应用于双组分聚氨酯汽车清漆,凭借其优异的漆膜外观、耐候性和抗石击性,树立了高性能汽车涂料的标杆。同时,该系列产品的残余单体含量低于0.1%,在工业卫生方面也树立了新标准。随着越来越多汽车制造企业关注减碳的话题,科思创也推出了部分生物基固化剂Desmodur® CQ ultra N7300,它含有70%可再生碳含量,这些碳主要来源于不与食物链竞争的植物淀粉原料,可以显著降低双组分聚氨酯清漆的碳足迹。此外,它只需极少的配方调整,就保持与化石基固化剂相似的高性能。目前,我们正在亚太地区与产业链的合作方共同推进产品的验证。

Our products serve many downstream application industries. Taking the automotive industry as an example, the Desmodur® ultra N series of crosslinkers have been widely used in two-component polyurethane automotive clear coats, setting a benchmark for high-performance automotive coatings with their excellent film appearance, weather resistance, and stone chip resistance. At the same time, the residual monomer content of this series of products is less than 0.1%, also setting a new standard in industrial hygiene. As more and more automobile manufacturers focus on carbon reduction, Covestro has also launched the partially bio-based curing agent Desmodur® CQ ultra N7300, which contains 70% renewable carbon content, mainly derived from plant starch raw materials that do not compete with the food chain, and can significantly reduce the carbon footprint of two-component polyurethane clear coats. In addition, it maintains similar high performance to fossil-based curing agents with minimal formulation adjustments. Currently, we are working with partners in the value chain in the Asia Pacific to promote product validation.

此外,作为汽车内饰胶水性化的先驱,科思创的水性聚氨酯分散体Dispercoll® U 54和U 56因其优异的初黏性和持黏时间,成功地应用于汽车内饰件包覆胶。在此基础上,针对极端高温天气对内饰抗老化能力的挑战,科思创又进一步推出了Dispercoll® U 86 PLUS和U 88 PLUS水性聚氨酯分散体。该新升级方案兼顾低VOC、低气味等环保优势,提高了产品的耐高温和耐湿热性能,保障内饰胶粘剂粘接表现长期稳定性,从而能轻松驾驭各种内饰包覆应用场景。

In addition, as a pioneer in the waterborne transformation of automotive interior adhesives, Covestro's waterborne polyurethane dispersions Dispercoll® U 54 and U 56 have been successfully applied to automotive interiors bonding due to their excellent initial tack and open time. Building on this, in response to the challenge of extreme high-temperature weather on the aging resistance of interior parts, Covestro further launched Dispercoll® U 86 PLUS and U 88 PLUS waterborne polyurethane dispersions. This new upgraded solution combines low VOC, low odor, and other environmental advantages, improves the product's high-temperature and humid heat resistance, ensures the long-term stability of interior adhesive bonding performance, and can easily handle various interior covering application scenarios.

这样的例子还有很多。科思创从不满足于现状,通过持续的产品创新,我们为客户创造更多的价值,推动行业高质量发展。

There are many such examples. Covestro is never satisfied with the status quo. Through continuous product innovation, we create more value for customers and promote high-quality development of the industry.

《中国涂料》China Coatings

科思创始终致力于创新发展。可以看出,近年来科思创在继续保持传统优势的同时,聚焦更丰富的产品组合和多元化技术平台。请问科思创围绕哪些关键创新维度,渗透哪些新的涂料应用领域,助力客户缩短研发周期、实现跨周期增长的?将为客户提供哪些创新解决方案?

Covestro has always been committed to innovations. It can be seen that in recent years, while continuing to maintain traditional advantages, Covestro has focused on a richer product portfolio and diversified technology platforms. Could you tell us around which key innovation dimensions Covestro is penetrating new coating application fields, helping customers shorten R&D cycles and achieve cross-cycle growth? What innovative solutions will be provided to customers?

科思创 Covestro

简而言之,科思创的创新原则建立在三大核心维度之上:性能、效率与法规合规。在性能方面,我们关注延长终端产品的使用寿命,提升产品外观设计;在效率方面,我们关注快速固化、低温烤漆等技术,助力下游产业实现涂装、粘接工艺效率提升和节能减排;在法规方面,我们在低VOC环保型方案,包括水性和高固技术,以及采用替代性原材料的低碳解决方案领域持续发力。接下来,我会介绍几款科思创针对行业趋势开发的创新型涂料解决方案。

In short, Covestro's innovation principles are built on three core dimensions: performance, efficiency, and regulatory compliance. In terms of performance, we focus on extending the service life of end products and enhancing product appearance design; in terms of efficiency, we focus on technologies such as fastdrying and low-temperature baking to help downstream industries improve coating and bonding process efficiency and achieve energy conservation and emission reduction; in terms of regulations, we continue to focus on low VOC environmentally friendly solutions, including waterborne and high-solid technologies, as well as low-carbon solutions using alternative raw materials. Next, I will introduce several innovative coating solutions developed by Covestro in response to industry trends.

提升新能源汽车的外观

摆脱了传统燃油车的黑、白、灰,我们看到更多闪亮多彩的新能源汽车在道路上行驶,表达出年轻一代车主的个性。我们正在推动双组分聚氨酯清漆替代1K TSA/酸性环氧涂料,同时配套水性底漆、中涂和底色漆的方案。科思创的高固型汽车清漆综合解决方案,包含了高性能树脂和固化剂的组合,满足环保型涂料的标准(VOC含量<420 g/L),带来优异的漆膜外观,并能提高喷涂效率。客户可以从Hybrane™ CY 240/245/268丙烯酸树脂和Desmophen®670BA聚酯树脂中选择,与Desmodur® ultra N系列固化剂组合使用,从而实现更佳的光泽和流平性。如果客户对低碳型清漆解决方案感兴趣,我们已开发出多款部分生物基固化剂产品,如Desmodur® CQ ultra N7300和N7400。

Enhancing the appearance of new energy vehicles

Moving beyond the traditional black, white, and gray look of conventional fuel vehicles, we see more bright and colorful new energy vehicles on the road, expressing the personality of the younger generation of car owners. We are promoting two-component polyurethane clear coat solutions to replace 1K TSA/acid epoxy, along with waterborne primer, mid-coat, and basecoat solutions. Covestro's high-solid automotive clear coat solution, including a combination of high-performance resins and crosslinkers, meets the standards for environmentally friendly coatings (VOC content <420g/L), delivers excellent film appearance, and improves spraying efficiency. Customers can choose from Hybrane™ CY 240/245/268 acrylic resins and Desmophen® 670BA polyester resin, combined with Desmodur® ultra N series, to achieve better gloss and leveling. If customers are interested in low-carbon clear coat solutions, we have developed several partially bio-based curing agent products, such as Desmodur® CQ ultra N7300 and N7400.

提升轨交车辆涂装效率

随着市场对提高效率的涂料解决方案需求增长,科思创的快速固化技术已在多个行业推广,帮助客户获得竞争优势。例如,在轨道交通行业,高铁车身腻子通常采用不饱和聚酯体系,需人工刮涂。科思创推出的高铁金属部件超快固底面合一涂料解决方案可实现自动化涂装与打磨,以及室温快速固化,大幅提高车辆涂装效率,预计可缩短40%生产周期。

Improving rail vehicle coating efficiency

With the growing market demand for efficiency-improving coating solutions, Covestro's fastdrying technology has been promoted in multiple industries, helping customers gain competitive advantages. For example, in the rail transportation industry, high-speed rail body putty typically uses unsaturated polyester systems that require manual application. Covestro's ultra-fast drying primer-surfacer solution for high-speed rail metal parts enables automated coating and polishing, as well as room temperature rapid curing, significantly improving vehicle coating efficiency and is expected to shorten the production cycle by 40%.

新能源行业多样化创新

亚太地区占据全球风能和太阳能产品生产的80%以上,中国更是这一领域的核心市场。科思创积极与整个价值链紧密协作,持续提供前沿创新解决方案。

在风能领域,科思创推出了水性和聚天门冬氨酸酯基风机叶片涂料解决方案,并不断提升其性能。双组分水性风机叶片面漆,采用Bayhydrol® A和Bayhydrol® U,也就是聚丙烯酸酯与聚氨酯树脂复合技术,为涂层赋予卓越耐久性,具有优异的耐酸碱性、耐磨性和耐候性。同时,这一配方可实现更长的适用期、更低的VOC排放,以及快速干燥、便捷混合和施工高效等特性。

针对风机叶片高速旋转时面临的挑战,科思创开发了基于聚天门冬氨酸酯技术的前缘保护(LEP)解决方案。这种高性能树脂兼具优异弹性和强度,能有效吸收高速雨滴冲击产生的动能,能有效提升叶片耐雨蚀性能。目前,该新技术已经由重点客户商用化,并收获终端用户的高度评价。

在太阳能领域,今年,科思创聚氨酯复合材料光伏组件边框已实现突破性发展,累计出货量超过3吉瓦,相当于500万块常规光伏板。我们为聚氨酯拉挤型材框架开发的水性涂料解决方案,能进一步提升了光伏组件边框耐候性能与环保性。

此外,科思创在2024年成功实现了创新半透明柔性复合前板的首个商业化应用,专为便携式光伏和建筑集成/附加光伏系统设计。这种采用科思创特种树脂制造的柔性前板不仅保持高透明度,还能将组件重量较传统玻璃前板减轻高达70%,为光伏应用开辟了全新可能。

Diversified innovation in the new energy industry

The Asia Pacific region accounts for more than 80% of global wind and solar product production, with China being the core market in this field. Covestro actively collaborates closely with the entire value chain to continuously provide cutting-edge innovative solutions.

In the wind energy, Covestro has launched waterborne and polyaspartic-based wind turbine blade coating solutions and continuously improves their performance. The two-component waterborne wind turbine blade topcoat, using Bayhydrol® A and Bayhydrol® U, which is a technology of polyacrylate and polyurethane resins, gives the coating excellent durability with outstanding acid and alkali resistance, abrasion resistance, and weather resistance. At the same time, this formulation can achieve a longer shelf life, lower VOC emissions, as well as fast drying, easy mixing, and efficient application.

In response to the challenges faced by wind turbine blades during high-speed rotation, Covestro has developed a Leading Edge Protection (LEP) solution based on polyaspartic technology. This high-performance resin combines excellent elasticity and strength, effectively absorbing the kinetic energy generated by high-speed raindrops, and effectively improving the blade's rain erosion resistance. Currently, this new technology has been commercialized by key customers and has received high praise from end users.

In the solar energy, this year, Covestro's polyurethane composite material photovoltaic module frames have achieved breakthrough development, with cumulative shipments exceeding 3 gigawatts, equivalent to 5 million conventional photovoltaic panels. Our waterborne coating solution developed for polyurethane pultrusion profile frames further enhances the weather resistance and environmental friendliness of photovoltaic module frames.

In addition, Covestro successfully achieved the first commercial application of innovative semi-transparent flexible composite front sheets in 2024, specifically designed for portable photovoltaic and building-integrated/attached photovoltaic systems. This flexible front sheet made with Covestro specialty resins not only maintains high transparency but also reduces the weight of the module by up to 70% compared to traditional glass front sheets, opening up new possibilities for photovoltaic applications.

建筑涂料:聚焦细分应用场景

专注于建筑涂料高性能细分市场,我们推出多项突破性创新涂料解决方案。我们自主研发并拥有专利保护的新型水性聚氨酯分散体产品Bayhydrol® UH 2897,专为高性能屋面防水涂料设计,具备极低吸水率、优异力学性能和卓越耐久性,能够有效降低建筑物全生命周期维护成本,为客户创造长期价值。

同时,科思创本土研发团队成功开发了创新型HDI基聚异氰酸酯预聚物Desmodur® ultra E 30800,这款为聚天门冬氨酸酯涂料体系量身定制的固化剂,可广泛应用于地坪涂料、防腐蚀涂料及美缝剂等领域。该产品在保持快速固化特性的同时,显著延长了施工可操作时间,并具备优异的耐水性、耐磨性和耐候性,完美平衡了施工效率与涂层性能。

Construction coatings: Focus on niche market

Focusing on the high-performance segment of the building coatings market, we have launched several breakthrough innovative coating solutions. Our newly developed and patent-protected waterborne polyurethane dispersion Bayhydrol® UH 2897, designed for high-performance roof waterproofing, features extremely low water absorption, excellent mechanical properties, and outstanding durability, effectively reducing the lifecycle maintenance costs of buildings and creating long-term value for customers.

At the same time, Covestro's local R&D team has successfully developed the innovative HDI-based polyisocyanate prepolymer Desmodur® ultra E 30800, a crosslinker tailored for polyaspartic coating systems, which can be widely used in floor coatings, anti-corrosion coatings, and grout sealants. This product significantly extends the workable time while maintaining fast drying performance and features excellent water resistance, abrasion resistance, and weather resistance, perfectly balancing application efficiency and coating performance.

工业涂料的新突破

在家具和消费电子行业,科思创推出一款具有高交联密度特点的Bayhydrol® UV 2901紫外光固化聚氨酯分散体,打破了水性UV涂料配方设计的局限性。它既可以用于传统水性UV涂料体系,显著提升涂料硬度(可实现大于6H的硬度)、耐化性、耐水性和机械性能,也能与单组分水性丙烯酸或聚氨酯分散体组合使用,满足不通过应用场景的需求。它与多种基材具有优异的附着力,可广泛用于消费电子、木器家具等工业涂装领域,实现高性能与涂装效率。

科思创还专为中国木器涂料市场研发了一款创新型TDI基聚异氰酸酯预聚物,扩充了Desmodur® E系列产品,完美契合本土客户的需求。这款高性能单组分潮气固化木器底漆解决方案具备卓越的应用特性:优异的硬度表现确保漆膜坚固耐用;强效封闭单宁酸能力有效防止木材中的活性成分渗出;即使在低温环境下施工也能实现快速打磨,显著提升涂装效率。

New breakthroughs in industrial coatings

In the furniture and consumer electronics industries, Covestro has launched Bayhydrol® UV 2901, a UV-curable polyurethane dispersion with high crosslinking density, breaking the limitations of waterborne UV coating formulation design. It can be used in traditional waterborne UV coating systems, significantly improving coating hardness (achieving hardness greater than 6H), chemical resistance, water resistance, and mechanical properties, and can also be combined with one-component waterborne acrylic or polyurethane dispersions to meet the needs of different application scenarios. It has excellent adhesion to various substrates and can be widely used in consumer electronics, wooden furniture, and other industrial coating fields, achieving high performance and coating efficiency.

Covestro has also developed an innovative TDI-based polyisocyanate prepolymer specifically for the Chinese wood coating market, expanding the Desmodur® E series products to perfectly match the needs of local customers. This high-performance one-component moisture-curing wood primer solution has excellent application performances: outstanding hardness ensures durable film; strong tannin acid sealing capability effectively prevents active components in wood from seeping out; and it enables rapid sanding even in low-temperature environments, significantly improving coating efficiency.

《中国涂料》China Coatings

科思创位于上海的涂料与胶粘剂配方实验室完成扩建,其优势及重要意义是什么?将通过哪些具体方式为亚太地区客户提供有力赋能?

Covestro has completed the expansion of our Coatings and Adhesives Laboratory in Shanghai. What are the advantages and significance of Covestro's Shanghai laboratory? What specific ways will it use to provide strong empowerment to customers in the Asia-Pacific region?

科思创 Covestro

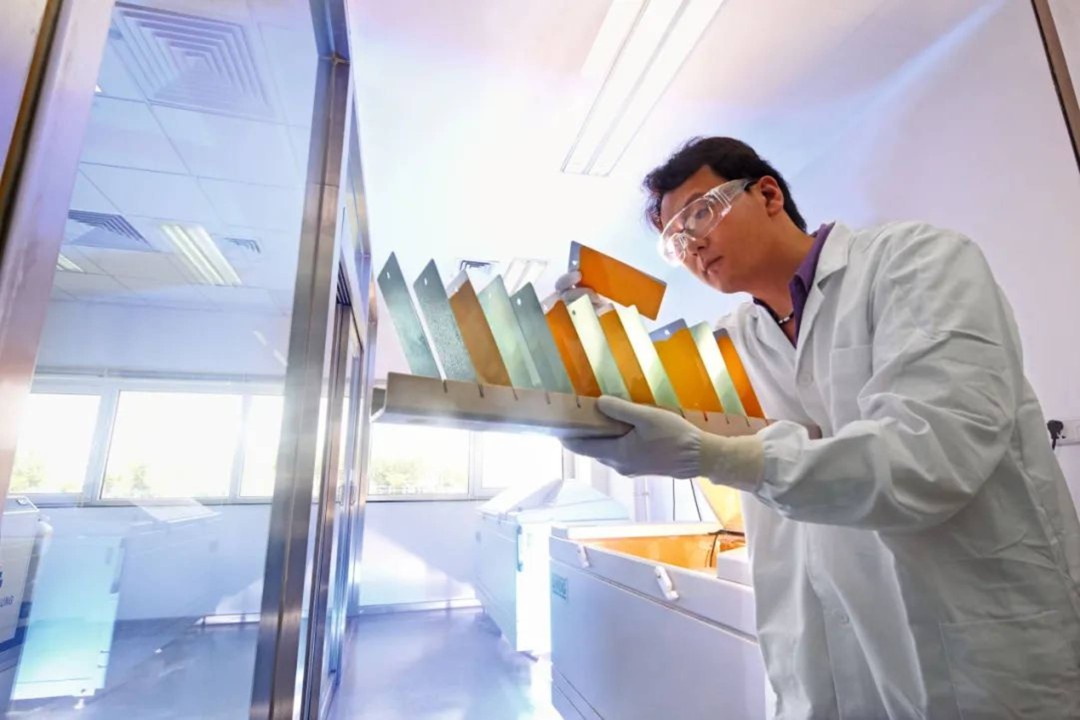

最近,我们完成了位于上海的涂料与胶粘剂配方实验室的扩建项目,该实验室作为科思创亚太创新中心的重要组成部分,扩建后实验室面积超过3000平方米,较之前增加约20%,并配备了先进的实验设备,其中包括一套用于水性聚氨酯分散体的全新合成装置,可显著提升工艺放大、问题排查和客户样品制备的效率。进一步提升为亚太地区客户提供创新型产品和解决方案的速度和能力。

Recently, we completed the expansion of our Coatings and Adhesives Laboratory in Shanghai. As an important part of Covestro's Asia Pacific Innovation Center, the expanded laboratory covers an area of over 3,000 square meters, an increase of about 20% compared to before, and is equipped with advanced experimental equipment, including a new synthesis device for waterborne polyurethane dispersions, which can significantly improve the efficiency of process scale-up, troubleshooting, and customer sample preparation. This further enhances our speed and capability to provide innovative products and solutions to customers in the Asia Pacific region.

《中国涂料》China Coatings

作为为涂料行业不断提供创新解决方案的供应商,如何看待目前的涂料市场,对于未来市场和涂料行业的发展有哪些预期?

As a supplier continuously providing innovative solutions for the coating industry, how do you view the current coating market, and what expectations do you have for the future market and development of the coating industry?

科思创 Covestro

2023年至2028年,全球涂料市场的年复合增长率约为2.5%(数据来源:S&P Global),亚太地区特别是中国市场依然是全球涂料市场发展的引擎。

中国涂料市场正处于转型升级的关键期,即市场从“规模增长”向“价值增长”转型。未来行业的集中度将进一步步提高,大型涂料企业通过规模和创新技术优势增加市场占有率。而一些细分市场和新的应用场景将带来远高于行业增速的发展收益。敏锐的市场洞察和创新力将帮助企业在未来新周期实现更好的增长。

科思创正在持续投入的几个领域,它们都有着一些共性,比如效率提升、节能减排,采用可替代性原材料代替化石基原料,与中国的“双碳目标”推进以及绿色转型的趋势紧密相关,特别是在新能源汽车、新能源、消费电子以及建筑等充满活力的市场领域。

我们相信,通过不断创新和坚持可持续发展,涂料行业将迎来更加绿色、高效、智能的未来。

The global coating market's compound annual growth rate from 2023 to 2028 is about 2.5% (data source: S&P Global), with the Asia Pacific region, especially the Chinese market, remaining the engine of global coating market development.

The Chinese coating market is at a critical period of transformation and upgrading, transitioning from "scale growth" to "value growth." The industry concentration will further increase in the future, with large coating enterprises increasing market share through scale and innovative technology advantages. Some segmented markets and new application scenarios will bring development benefits far higher than the industry growth rate. Market insight and innovation will help enterprises achieve better growth in the new cycle.

Covestro is continuously investing in several areas that share commonalities such as efficiency improvement, energy conservation and emission reduction, and using alternative raw materials to replace fossil-based raw materials, closely related to China's "dual carbon goals" and green transformation trends, especially in industries such as new energy vehicles, new energy, consumer electronics, and construction.

We believe that through continuous innovation and adherence to sustainable development, the coating industry will usher in a greener, more efficient, and smarter future.

《中国涂料》China Coatings

2025年是“十四五”规划收官之年,也是“十五五”规划谋篇布局之年。请畅谈一下,科思创未来的发展愿景。

2025 is the final year of the "14th Five-Year Plan" and the year for planning the "15th Five-Year Plan." Please share Covestro's plan and vision for future growth.

科思创 Covestro

中国作为科思创全球最大的单一市场,占全球销售额约23%。自2001年起,科思创在中国的累计投资已超过40亿欧元,彰显了对中国市场的长期承诺。

通过过去十多年集中的生产能力投资,我们大大加强了中国和亚太市场可持续涂料和胶粘剂原材料产品的供应和服务能力,其中包括于2023年竣工的位于科思创上海一体化基地的全新水性聚氨酯分散体(PUD)工厂,2024年投产的位于印度的新三聚体生产装置,显著提升本土的供货稳定性和服务响应速度。目前我们在亚太区销售的涂料和胶粘剂原材料产品的本土化生产比例已达75%。更高的本土化程度也为亚太和中国客户带来了切实的益处,无论是产品的供应还是竞争力。

同时,推进数字化也是科思创“可持续未来”战略的重要一环。数字化正在推动我们各个方面的工作方式变革。依托数字技术我们为客户提供高效响应的商务流程和服务(如线上索样、订单查询和货物追踪功能等),提升客户体验。

在创新方面,我们的数字化主要围绕数字化基础设施与核心能力两大方向展开。在基础设施方面,我们的树脂合成实验室整合了IoT技术实现研发数据自动采集,加速了新产品开发流程;针对快速迭代的市场需求建立了AI驱动的配方性能预测模型,提高了应用开发的效率;并投入了一系列实验室自动化设备,其中针对配方的自动化工作站近期已经进入验收阶段。在核心能力建设上,科思创专注于材料与加工模拟,计算化学和数据科学等领域。这些举措使科思创的创新力始终处于行业领先地位。

展望未来,科思创的愿景是实现“全面循环”,成为低碳材料和循环经济领域的领导者。科思创将加大在低碳型技术、替代性原材料和创新回收工艺等领域的研发投入。在涂料和胶粘剂领域,我们将推动本地创新与全球协同,推出涵盖多产品线和技术体系的低碳型创新涂料和胶粘剂综合解决方案,助力产业链合作方实现“近零排放”目标,促进共赢发展。

China, as Covestro's largest single market globally, accounting for about 23% of global sales. Since 2001, Covestro's cumulative investment in China has exceeded 4 billion euros, demonstrating its long-term commitment to the Chinese market.

Through concentrated production capacity investments over the past decade, we have greatly strengthened our supply and service capabilities for sustainable coating and adhesive raw material products in the Chinese and Asia Pacific markets. This includes the new waterborne polyurethane dispersion (PUD) plant at Covestro's Shanghai integrated site completed in 2023, and the new trimer production facility in India that started operation in 2024, significantly improving local supply stability and service response speed. Currently, the localization of coating and adhesive raw material products we sell in the region has reached 75%. A higher degree of localization also brings tangible benefits to Asia Pacific and Chinese customers, both in terms of product supply and competitiveness.

At the same time, advancing digitalization is an important part of Covestro's "Sustainable Future" strategy. Digitalization is driving transformation in our way of working across all areas. Leveraging digital technology, we continuously optimize business processes and provide first-class services (such as online sampling, order checking and delivery tracking) to enhance customer experience.

Our digital R&D mainly focuses on two directions: digital infrastructure and core capabilities. In terms of infrastructure, our resin synthesis laboratory has integrated IoT technology to achieve automatic collection of R&D data, accelerating the new product development process; established AI-driven formulation performance prediction models for rapidly iterating market demands, improving the efficiency of application development; and invested in a series of laboratory automation equipment, with the automated workstation for formulations recently entering the acceptance phase. In building core capabilities, Covestro focuses on materials and processing simulation, computational chemistry, and data science. These initiatives keep Covestro's innovation power at the forefront of the industry.

Looking to the future, Covestro's vision is to achieve "comprehensive circularity" and become a leader in the field of low-carbon materials and circular economy. Covestro will increase R&D investment in low-carbon technology, alternative raw materials, and innovative recycling processes. In the coatings and adhesives field, we will promote local innovation and global collaboration, launching low-carbon innovative coating and adhesive solutions covering multiple product lines and technology systems, helping value chain partners achieve "near-zero emission" goals and promoting win-win development.

分享好友

分享好友